N-800A SMT Vacuum Degassing Machine

Encapsulation and Conformal Coating are processes implemented to enhance the reliability of electronic products, bubble defects can cause premature failure of the electronic circuits. Multiple factors contribute to the bubble defects in encapsulation/conformal coating processes, as such, eradicating the bubbles is a painfully challenging task. With years of expertise in the encapsulation and conformal coating, Youngpool Technology has designed and developed a solution to address the bubble defect – the N-800A series Automatic Vacuum Degassing System. The N-800A is an inline degassing system using vacuum principle that will effectively mitigate the bubble defects, it enables production of bubble-free electronic products that meet various industrial reliability standards.

● Inline configuration for easy integration into production line

● Single lane-single chamber configuration

● Degassing accomplished using vacuum and heat

● Adjustable vacuum profile

● Max. PCB size : 500mm x 500mm

● Easy to operate

TECHNICAL SPECIFICATIONS

|

PCB Size |

Applicable PCB(mm) |

500 × 500 |

|

Top Clearance(mm) |

50 |

|

|

Bottom Clearance(mm) |

50 |

|

|

Max. PCB Weight(kg) |

3.5 |

|

|

Conveyor Specifications |

Conveyor Width(mm) |

100-500 |

|

Transfer Height(mm) |

900±20 |

|

|

Conveyor Type |

Chain Conveyor

|

|

|

Transfer Direction |

Left to Right |

|

|

Transfer Method |

Chain transfer | |

|

Transfer Time(mm/s) |

Max. 500 |

|

|

SMEMA |

Standard |

|

|

Function |

Applicable Applications |

Underfill and Conformal Coating |

|

Viscosity of Material |

9,000 cps or below |

|

|

Vacuum Pump Performance(m³/h) |

60 |

|

|

Max. Vacuum Level(Pa) |

4 |

|

|

Typical Degassing Cycle Time(Sec) |

40-300 |

|

|

Dimensions and Control |

Control and User Interface |

Industrial Personal Computer |

|

Dimensions(mm) |

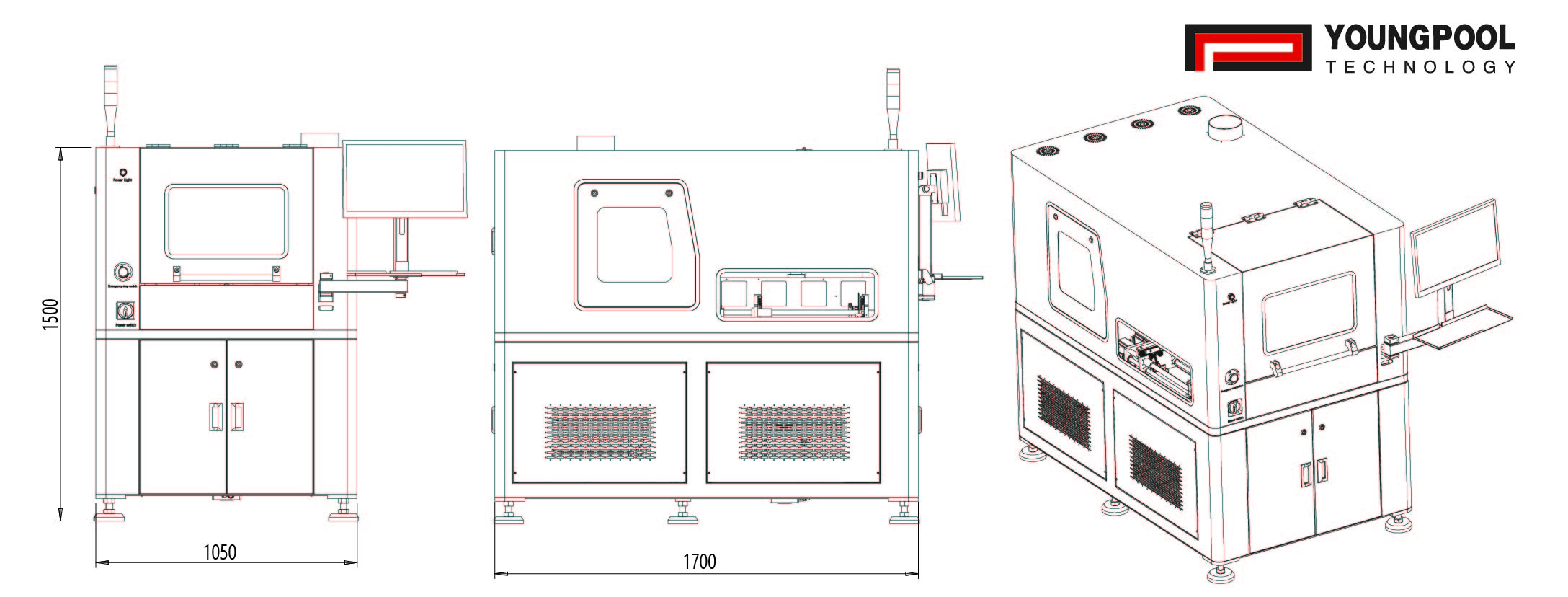

1050(W)×1700(L)×1500±20(H) |

|

|

Weight(kg) |

1100 |

|

|

Electrical Requirements |

Voltage |

Three Phase, 380V, 50Hz |

|

Power(kW) |

4 |

|

|

Options and Accessories |

CCD visual monitoring |

Available as Option |

|

MES |

Available as Option |

|

|

Heat assisted degassing |

Available as Option |

|

|

Underneath Return Conveyor |

Available as Option |

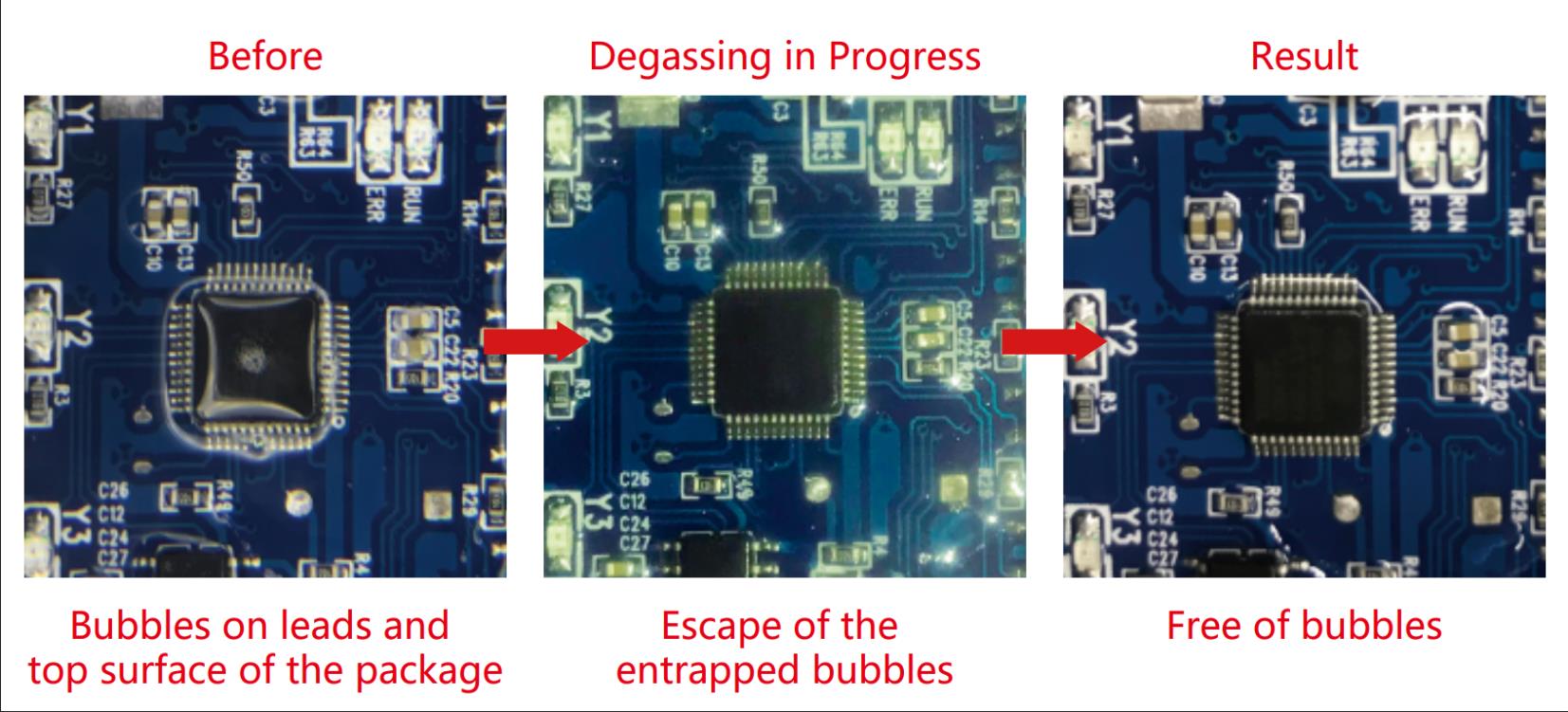

Illustrations of Degassing effect

Vacuum Degassing Machine Dimensions

● Published in Feb. 2024 , All Rights Reserved

● All specifications are subject to change as a result of technical developments or advances. For questions on our products, please contact Youngpool Technonlogy (information@youngpool.com) or our local representative(s)

IPv6 network supported

IPv6 network supported