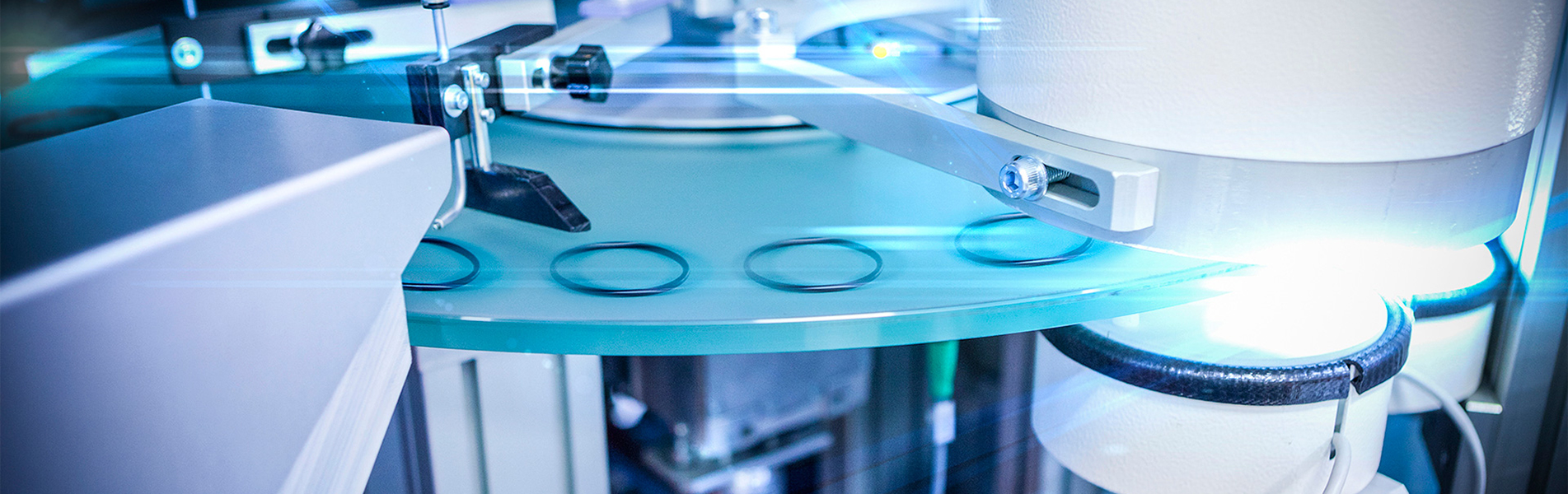

LD-5 Inline Laser Depaneling Machine

● Granite platform, high precision, stability and durability;

● Linear motor drive, high speed, low noise, no vibration;

● Linear scale positioning, repetition accuracy up to ±2 μm;

● Three section on-line track, high cutting efficiency;

● Large working size range, 400*400mm;

● Green light and UV sources are optional;

● Laser line width less than 20μm;

● External purification unit.

TECHNICAL SPECIFICATIONS

|

Model No. |

LD-5 |

|

|

Laser Type |

UV/Nano Secs/15W |

GREEN LIGHT/Nano Secs/35W |

|

X/Y Distances (mm) |

690*534 |

|

|

Z Axis Distances (mm) |

100 |

|

|

Working Area (mm) |

400*400 |

|

|

Granite platform flatness (mm) |

±0.01 |

|

|

Platform Accuracy |

Positioning accuracy (μm): ±3,Repeatibilty (μm): ±2 |

|

|

Platform Speed (mm/s) |

Maximum speed 1000mm/s, acceleration 10000mm/s² |

|

|

Laser Lifespan |

>20000 H |

|

|

Cutting Methods |

Scanning head mode, cutting range of 50*50mm |

|

|

Min. focus spot diameter |

≤20μm |

|

|

Machine Control System |

Integrated Vision, Laser Source and Movement |

|

|

Software Support |

Dxf or Gerber or common formats |

|

|

Power Consumption |

220V/50Hz/5KVA |

|

|

Operating Temperature |

15℃-35℃ |

|

|

Weight(kgs) |

1800 |

|

|

Dimensions (mm) |

1250(W) x 1400(D) x 1700(H) |

|

IPv6 network supported

IPv6 network supported