L-900 as SMT Industry pioneer in splicing system, not only can perfectly handle 8 ~ 24mm tape, but also has strong compatibility and the most powerful splicing passing ability. Deep pocket capability up to 9mm, strong splice tape adhesion strength of 5 kg and with the anti-torsion of 360 degrees. Therefore, L-900 is not only a intelligent splicing machine, but also a highly precise tool to improve SMT production efficiency

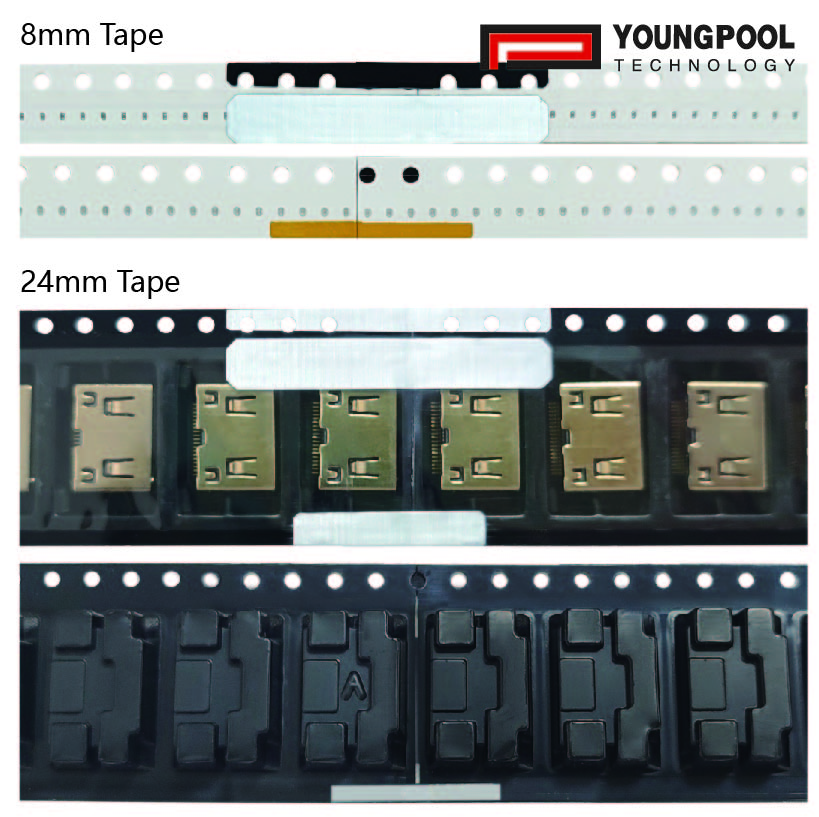

● Support 8, 12, 16, 24mm component tape width

● Support paper and embossed tape

● Support deep pocket up to 9mm

● Optional LCR verification for Capacitors and Resistors

● Independent X/Y/Z axis design for LCR verification

● Auto adjust LCR measurement probe for components size from 01005”

● Intelligent vision system

● Auto empty pocket detection with pre-cut stations and component pitch verification

● Excellent FPY up to 98%

● Support MES

TECHNICAL SPECIFICATIONS

|

Tape splicing system |

X axis Repeatability(mm) |

±0.01 |

|

Y axis Repeatability(mm) |

±0.01 |

|

|

Positioning Accuracy of tape(mm) |

±0.2 |

|

|

Information of component tape |

Component tape width(mm) |

8/12/16/24 |

|

Component pitch(mm) |

2/4/8/12/16/20/24 |

|

|

Component pocket depth max.(mm) |

9 |

|

|

Component tape thickness(8mm tape)(mm) |

0.25~1.25 |

|

|

Conveyor system |

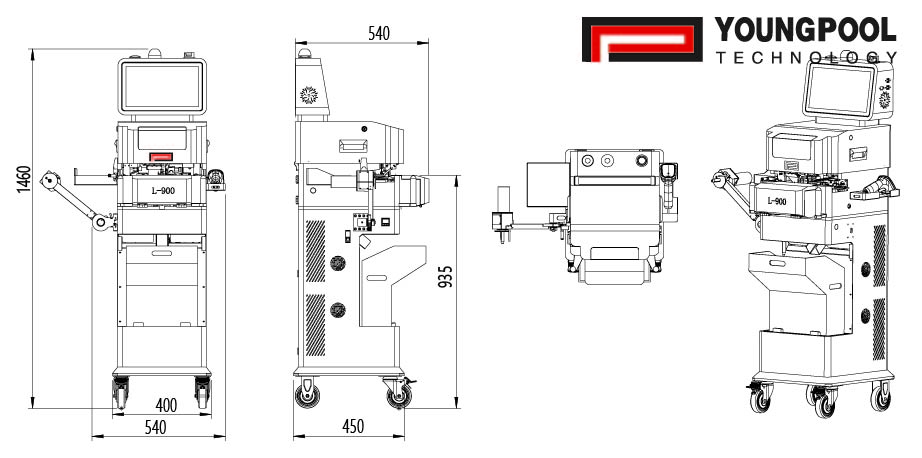

Conveyor height(mm) |

930±15 |

|

Rewinding device |

rewinding arm |

Standard one rewinding arm , optional Two rewinding arms |

|

Reel Size(mm) |

Max.Ø380,Optional Ø500 |

|

|

Max. load(kg) |

Max.20 |

|

|

Decoded mode |

Barcode scanner |

Standard |

|

Barcode camera attach on rewinding arm |

Optional |

|

|

Splicing Rate |

Cycle Time (sec) |

≤10S(not including LCR test time and manual feeding time) |

|

Splicing capacity |

Splicing FPY |

98% |

|

Splicing gap(mm) |

±0.1 |

|

|

Anti-torque capacity of the material inlet |

360 degrees (plastic strap, length of the material inlet at both ends is 250mm) |

|

|

Software contro |

Automatic component pitch identification |

Standard |

|

Component size comparison |

Standard |

|

|

BOM import wizard |

Standard |

|

|

OCR |

Optional |

|

|

LCR |

Measurement accuracy |

±0.05% |

|

Measurement range |

L:0μH-1000H,C:0pF-20mF,R:0Ω-20MΩ |

|

|

Measurement method |

Two-sided measurement value |

|

|

Test pass rate |

95%(01005 Component) |

|

|

Electricity |

Power supply mode |

24V DC 50Ah Lithium battery |

|

Battery time (when fully charged)(h) |

12-16 |

|

|

Power(W) |

Max.120 |

|

|

Facilities Requirements |

Weight(Kg) |

95 |

|

Reference Dimension(mm) |

540(W) × 540(L) × 1460(H) |

|

|

Other configurations are optional |

MES customization, Barcode printer, Component reels stop function, Rotational speed sensor function, Fool-proofing function for rewinding arm, Laser height measurement function,Auto return device, Auto tape width recognition, Auto tape pitch recognition for 12-24mm tape, Direct power supply, Wireless charging, Motion platform, Heavy motion platform. |

|

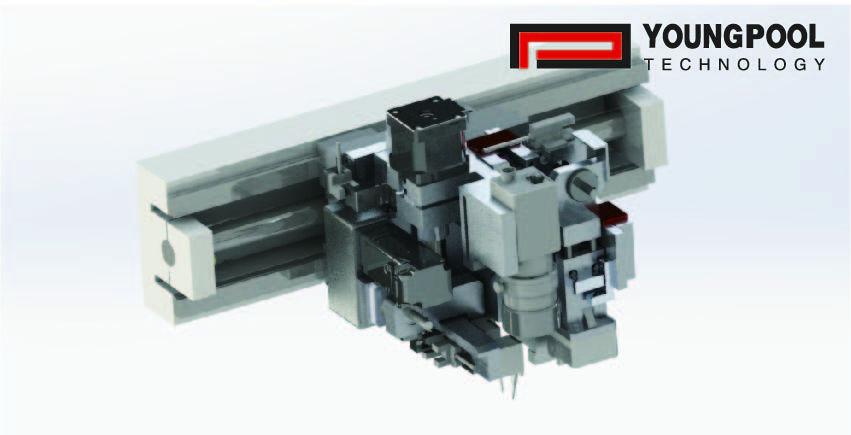

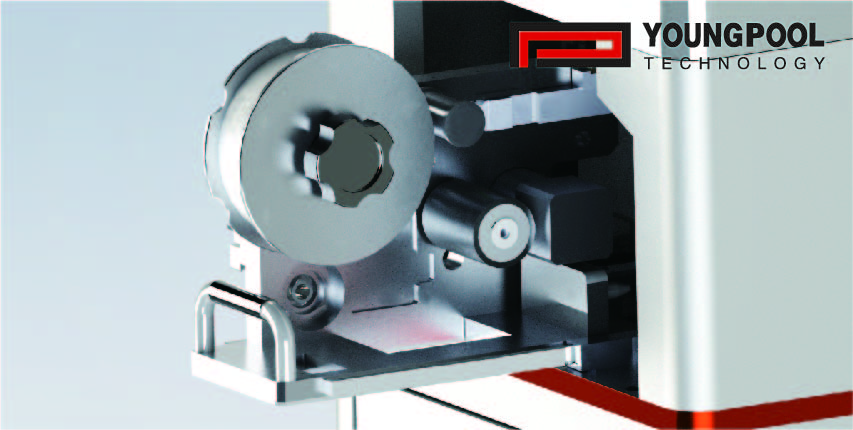

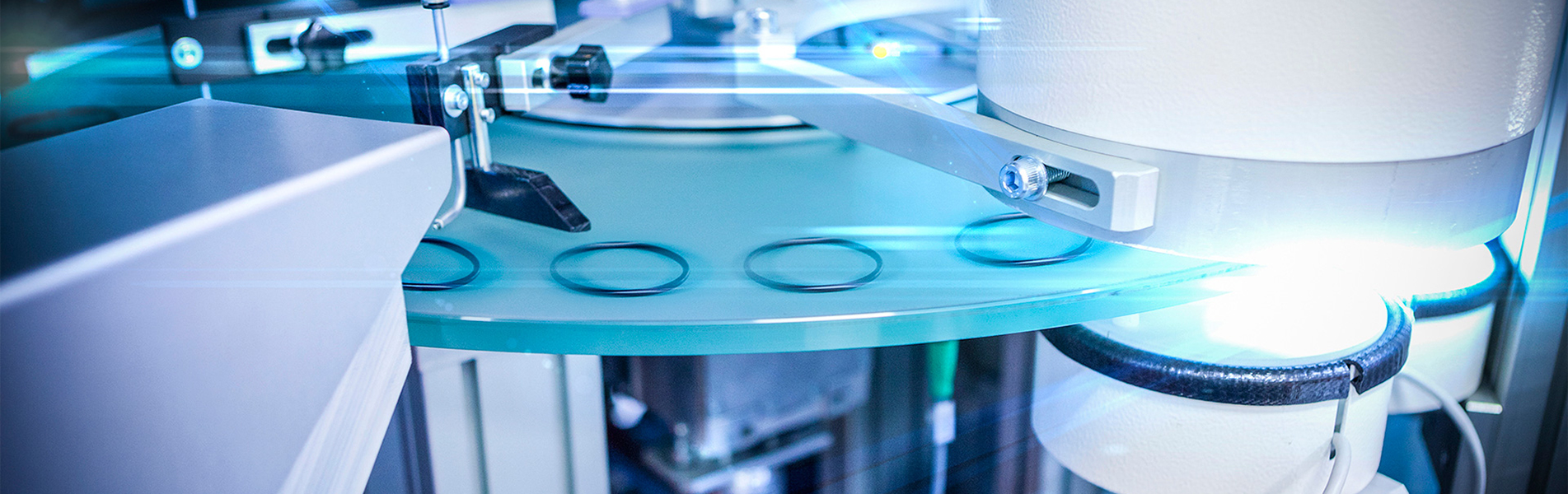

Illustrations of Automatic Splicing System

[Adhesion Independent axis: vision system, LCR measurement, Splicing mechanism.]

[Carrier Pull-out design: Splicing Tape feeding system.]

[Unique Splicing Tape design:Top side bonding ONLY]

Splicing Machine Dimensions

● Published in Feb. 2024 , All Rights Reserved

● All specifications are subject to change as a result of technical developments or advances. For questions on our products, please contact Youngpool Technonlogy (information@youngpool.com) or our local representative(s)

IPv6 network supported

IPv6 network supported