Categories

New Blog

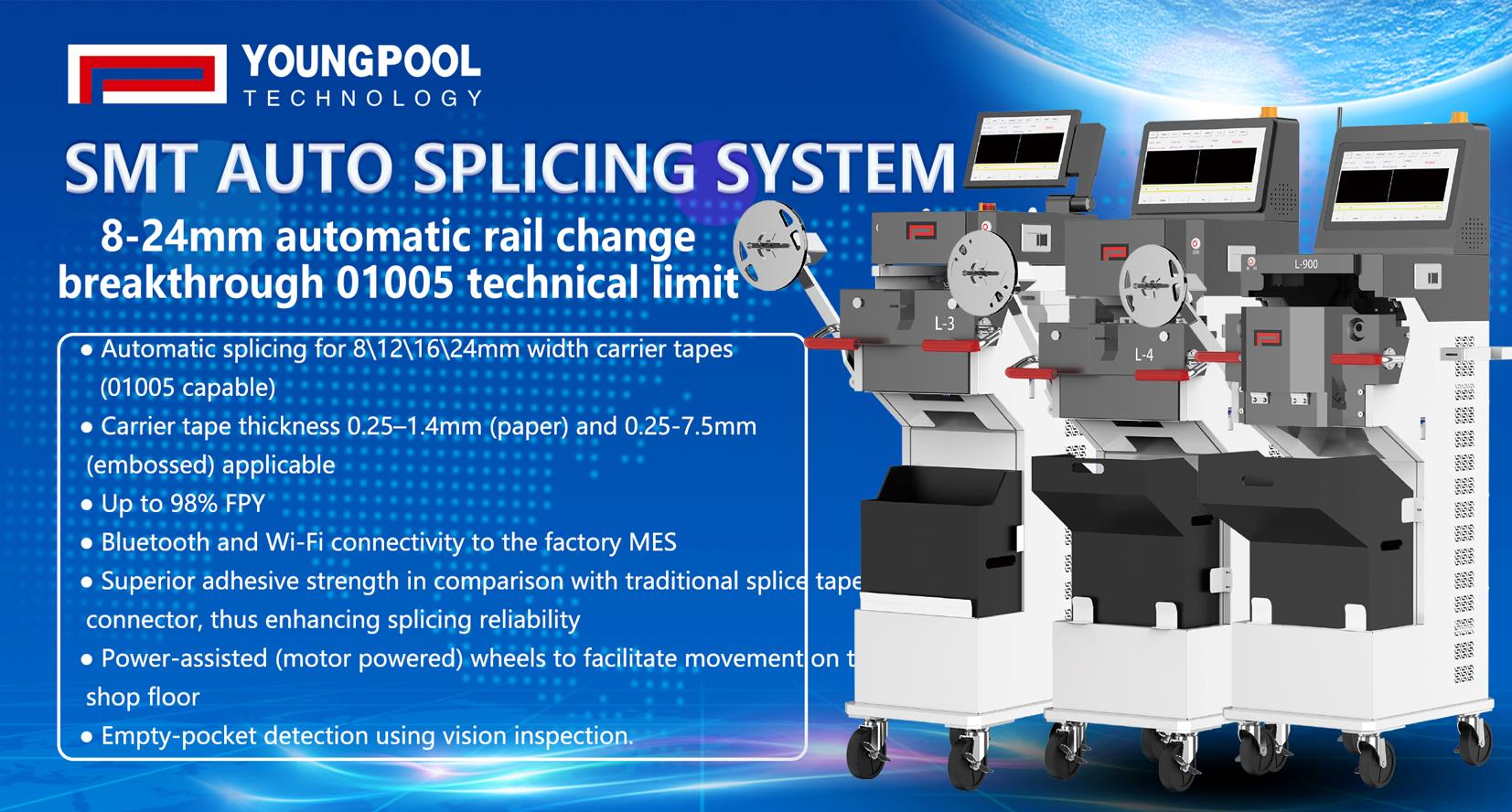

What are the features of SMT Splicing Machine?

Mar 15, 2022SMT Splicing equipment introduction:

SMT Splicing Machine can automatically detect the position, cut, and connect the two rolls of the same specifications with the tape. SMT Splicing Machine is easy to operate, greatly improve speed, save manpower and improve consumption efficiency. Professional for SMT automatic consumption line non-stop fast refueling.

SMT Splicing Machine technical parameters

Applicable material belt range: paper tape, width 8mm, thickness 0.25 ~ 1.4mm

Machine cycle (C/T) : 7.2s (excluding manual loading and unloading time)

Dimensions: length 515mm* width 470mm* height 1145mm

Working height: about 955mm

Power supply: external power supply 220VAC, with battery power supply time of 12-16 hours.

Operating ambient temperature: 0 ~ 40 degrees

Relative humidity: 45% ~ 65%

Weight: about 65KG

SMT feeder features:

1, SMT Splicing Machine with electrical, overall lightweight, convenient, suitable for a variety of workplaces;

2, SMT Splicing Machine pass rate reaches more than 98%.

3, SMT machine after connecting automatic material collection. Automatic identification of empty material position for different material belt detection;

4, SMT feeder universal interface, integrated CAM mechanism stable performance.

5, SMT Splicing Machine simple operation, greatly improve the speed of feeding, saving manpower, improve consumption efficiency, directly for the enterprise to improve economic benefits.

[Functional characteristics]

1. Automatic analysis and input of material specifications: scan code automatically input data, intelligent analysis of material specifications, without manual calculation and input.

2. Fast measurement and automatic determination: resistance, capacitance, inductance and other components can be measured. The system automatically switches the test gear, automatically reads the value and compares it with the material standard specification, automatically determines PASS or FAIL.

3. Visual comparison of devices: after scanning the bar code, the system automatically brings up the standard sample picture and automatically compares the component image.

4. Device search: the system provides a variety of search methods for users to quickly search, such as search for a project, search for a material number, a certain type of component, a certain specification, a batch of times, undetected devices, unqualified components, etc.

5. Report automatic generation function: at the end of the test, it can automatically generate component test report and component statistical report, and modify the report content according to the demand, convenient analysis and management.

6. Unified USE of SQL database function, can share data and management of multiple incoming material testing machines.Tags :